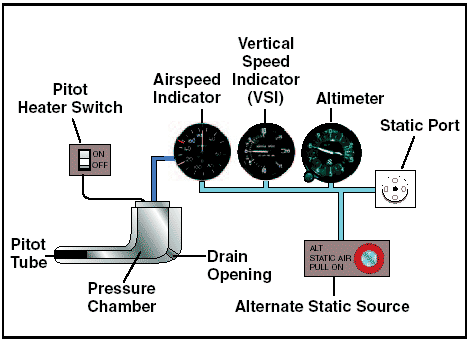

Flight InstrumentsFlight instruments enable an airplane to be operated with maximum performance and enhanced safety, especially when flying long distances. Manufacturers provide the necessary instruments, but to use them effectively, pilots need to understand how they operate. This page covers the operational aspects of the pitot-static system and associated instruments, the vacuum system and associated instruments, and the magnetic compass. Pitot-static flight instruments There are two major parts of the pitot-static system: the impact pressure chamber and lines, and the static pressure chamber and lines. They provide the source of ambient air pressure for the operation of the altimeter, vertical speed indicator (vertical velocity indicator), and the airspeed indicator.

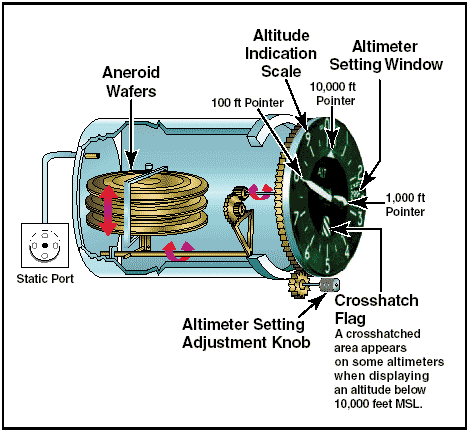

Figure 1: Pitot-static system and instruments. Impact pressure chamber and lines In this system, the impact air pressure (air striking the airplane because of its forward motion) is taken from a pitot tube, which is mounted in locations that provide minimum disturbance or turbulence caused by the motion of the airplane through the air. The static pressure (pressure of the still air) is usually taken from the static line attached to a vent or vents mounted flush with the side of the fuselage. This compensates for any possible variation in static pressure due to erratic changes in airplane attitude. The openings of both the pitot tube and the static vent must be checked during the preflight inspection to assure that they are free from obstructions. Blocked or partially blocked openings should be cleaned by a certificated mechanic. Blowing into these openings is not recommended because this could damage the instruments. As the airplane moves through the air, the impact pressure on the open pitot tube affects the pressure in the pitot chamber. Any change of pressure in the pitot chamber is transmitted through a line connected to the airspeed indicator, which utilizes impact pressure for its operation. Static pressure chamber and lines The static chamber is vented through small holes to the free undisturbed air, and as the atmospheric pressure increases or decreases, the pressure in the static chamber changes accordingly. Again, this pressure change is transmitted through lines to the flight instruments which utilize static pressure. An alternate source for static pressure is provided in some airplanes in the event the static ports become blocked. This source usually is vented to the pressure inside the cockpit. Because of the venturi effect of the flow of air over the cockpit, this alternate static pressure is usually lower than the pressure provided by the normal static air source. When the alternate static source is used, the following differences in the instrument indications usually occur: the altimeter will indicate higher than the actual altitude, the airspeed will indicate greater than the actual airspeed, and the vertical speed will indicate a climb while in level flight. Consult the Airplane Flight Manual or Pilot’s Operating Handbook (AFM/POH) to determine the amount of error. If the airplane is not equipped with an alternate static source, breaking the glass seal of the vertical speed indicator allows ambient air pressure to enter the static system. This makes the VSI unusable. Altimeter The altimeter measures the height of the airplane above a given pressure level. Since it is the only of the flight instruments that gives altitude information, the altimeter is one of the most vital flight instruments in the airplane. To use the altimeter effectively, its operation and how atmospheric pressure and temperature affect it must be thoroughly understood. A stack of sealed aneroid wafers comprises the main component of the altimeter. These wafers expand and contract with changes in atmospheric pressure from the static source. The mechanical linkage translates these changes into pointer movements on the indicator.

Figure 2: Altimeter. Principle of operation The pressure altimeter is an aneroid barometer that measures the pressure of the atmosphere at the level where the altimeter is located, and presents an altitude indication in feet. The altimeter uses static pressure as its source of operation. Air is denser at sea level than aloft, so as altitude increases, atmospheric pressure decreases. This difference in pressure at various levels causes the altimeter to indicate changes in altitude. The presentation of altitude varies considerably between different types of altimeters. Some have one pointer while others have two or more. Only the multipointer type will be discussed on this page. The dial of a typical altimeter is graduated with numerals arranged clockwise from 0 to 9. Movement of the aneroid element is transmitted through gears to the three hands that indicate altitude. The shortest hand indicates altitude in tens of thousands of feet; the intermediate hand in thousands of feet; and the longest hand in hundreds of feet. This indicated altitude is correct, however, only when the sea level barometric pressure is standard (29.92 inches of mercury), the sea level free air temperature is standard (+15°C or 59°F), and the pressure and temperature decrease at a standard rate with an increase in altitude. Adjustments for nonstandard conditions are accomplished by setting the corrected pressure into a barometric scale located on the face of the altimeter. Only after the altimeter is set does it indicate the correct altitude. Effect of nonstandard pressure and temperature If no means were provided for adjusting altimeters to nonstandard pressure, flight could be hazardous. For example, if flying from a high-pressure area to a low-pressure area without adjusting the altimeter, the actual altitude of the airplane would be LOWER than the indicated altitude. An old saying, “HIGH TO LOW, LOOK OUT BELOW” is a way of remembering which condition is dangerous. When flying from a low-pressure area to a high-pressure area without adjusting the altimeter, the actual altitude of the airplane is HIGHER than the indicated altitude.

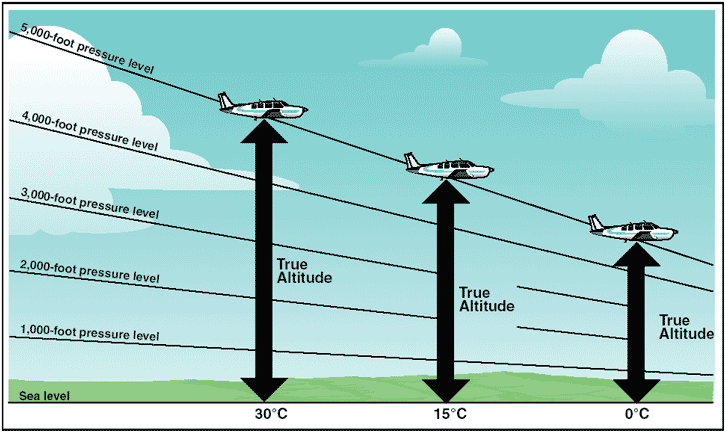

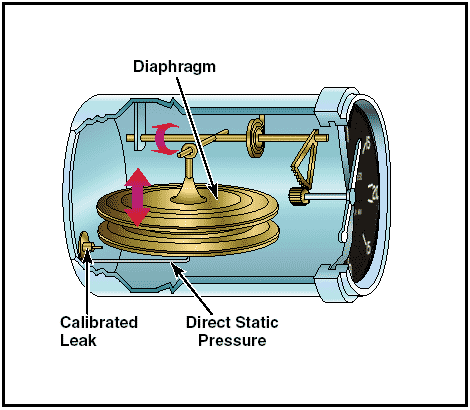

Figure 3: Effects of nonstandard temperature on an altimeter. Figure 3 shows how variations in air temperature also affect the altimeter. On a warm day, a given mass of air expands to a larger volume than on a cold day, raising the pressure levels. For example, the pressure level where the altimeter indicates 5,000 feet is HIGHER on a warm day than under standard conditions. On a cold day, the reverse is true, and the pressure level where the altimeter indicates 5,000 feet is LOWER. The adjustment to compensate for nonstandard pressure does not compensate for nonstandard temperature. If terrain or obstacle clearance is a factor in selecting a cruising altitude, particularly at higher altitudes, remember to anticipate that a colder-than-standard temperature places the airplane LOWER than the altimeter indicates. Therefore, it is necessary to use a higher indicated altitude to provide adequate terrain clearance. Modify the memory aid to “HIGH TO LOW OR HOT TO COLD, LOOK OUT BELOW.” Setting the altimeter Most altimeters are equipped with a barometric pressure setting window (sometimes referred to as the Kollsman window) providing a means to adjust the altimeter. A knob is located at the bottom of the instrument for this adjustment. To adjust the altimeter for variation in atmospheric pressure, the pressure scale in the altimeter setting window, calibrated in inches of mercury (in. Hg) and/or millibars (Mb), is adjusted to match the given altimeter setting. Altimeter setting is defined as station pressure reduced to sea level. However, an altimeter setting is accurate only in the vicinity of the reporting station. Therefore, the altimeter must be adjusted as the flight progresses from one station to the next. Many pilots confidently expect that the current altimeter setting will compensate for irregularities in atmospheric pressure at all altitudes, but this is not always true. The altimeter setting broadcast by ground stations is the station pressure corrected to mean sea level. It does not account for the irregularities at higher levels, particularly the effect of nonstandard temperature. However, if each pilot in a given area is using the same altimeter setting, each altimeter should be equally affected by temperature and pressure variation errors, making it possible to maintain the desired vertical separation between aircraft. When flying over high, mountainous terrain, certain atmospheric conditions can cause the altimeter to indicate an altitude of 1,000 feet, or more, HIGHER than the actual altitude. For this reason, a generous margin of altitude should be allowed—not only for possible altimeter error, but also for possible downdrafts that might be associated with high winds. To illustrate the use of the altimeter setting system, follow a flight from Before taking off from Love Field, the pilot receives a current altimeter setting of 29.85 from the control tower or automatic terminal information service (ATIS), and sets this value in the altimeter setting window. The altimeter indication should then be compared with the known airport elevation of 487 feet. Since most altimeters are not perfectly calibrated, an error may exist. When over Mineral Wells, assume the pilot receives a current altimeter setting of 29.94 and sets this in the altimeter window. Before entering the traffic pattern at The importance of properly setting the altimeter cannot be overemphasized. Assume that the pilot did not adjust the altimeter at When entering the Altimeter setting 29.94 Current altimeter setting 29.69 Difference .25 (Since 1 inch of pressure is equal to approximately 1,000 feet of altitude, .25 * 1,000 feet = 250 feet.) When determining whether to add or subtract the amount of altimeter error, remember that, when the actual pressure is lower than what is set in the altimeter window, the actual altitude of the airplane will be lower than what is indicated on the altimeter. Altimeter operation There are two means by which the altimeter pointers can be moved. The first is a change in air pressure, while the other is an adjustment to the barometric scale. When the airplane climbs or descends, changing pressure within the altimeter case expands or contracts the aneroid barometer. This movement is transmitted through mechanical linkage to rotate the pointers. A decrease in pressure causes the altimeter to indicate an increase in altitude, and an increase in pressure causes the altimeter to indicate a decrease in altitude. Accordingly, if the airplane is flown from a pressure level of 28.75 in. Hg. to a pressure level of 29.75 in. Hg., the altimeter would show a decrease of approximately 1,000 feet in altitude. The other method of moving the pointers does not rely on changing air pressure, but the mechanical construction of the altimeter. Do not be confused by the fact that as the barometric pressure scale is moved, the indicator needles move in the same direction, which is opposite to the reaction the pointers have when air pressure changes. To illustrate this point, suppose the pilot lands at an airport with an elevation of 1,000 feet and the altimeter is correctly set to the current sea level pressure of 30.00 in. Hg. While the airplane is parked on the ramp, the pressure decreases to 29.50. The altimeter senses this as a climb and now indicates 1,500 feet. When returning to the airplane, if the setting in the altimeter window is decreased to the current sea level pressure of 29.50, the indication will be reduced back down to 1,000 feet. Knowing the airplane’s altitude is vitally important to a pilot. The pilot must be sure that the airplane is flying high enough to clear the highest terrain or obstruction along the intended route. It is especially important to have accurate altitude information when visibility is restricted. To clear obstructions, the pilot must constantly be aware of the altitude of the airplane and the elevation of the surrounding terrain. To reduce the possibility of a midair collision, it is essential to maintain altitude in accordance with air traffic rules. Types of altitude Altitude is vertical distance above some point or level used as a reference. There are as many kinds of altitude as there are reference levels from which altitude is measured, and each may be used for specific reasons. Pilots are mainly concerned with five types of altitudes: Indicated Altitude—That altitude read directly from the altimeter (uncorrected) when it is set to the current altimeter setting. True Altitude—The vertical distance of the airplane above sea level—the actual altitude. It is often expressed as feet above mean sea level (MSL). Airport, terrain, and obstacle elevations on aeronautical charts are true altitudes. Absolute Altitude—The vertical distance of an airplane above the terrain, or above ground level (AGL). Pressure Altitude—The altitude indicated when the altimeter setting window (barometric scale) is adjusted to 29.92. This is the altitude above the standard datum plane, which is a theoretical plane where air pressure (corrected to 15°C) equals 29.92 in. Hg. Pressure altitude is used to compute density altitude, true altitude, true airspeed, and other performance data. Density Altitude—This altitude is pressure altitude corrected for variations from standard temperature. When conditions are standard, pressure altitude and density altitude are the same. If the temperature is above standard, the density altitude is higher than pressure altitude. If the temperature is below standard, the density altitude is lower than pressure altitude. This is an important altitude because it is directly related to the airplane’s performance. As an example, consider an airport with a field elevation of 5,048 feet MSL where the standard temperature is 5°C. Under these conditions, pressure altitude and density altitude are the same—5,048 feet. If the temperature changes to 30°C, the density altitude increases to 7,855 feet. This means an airplane would perform on takeoff as though the field elevation were 7,855 feet at standard temperature. Conversely, a temperature of -25°C would result in a density altitude of 1,232 feet. An airplane would have much better performance under these conditions. Instrument Check—To determine the condition of an altimeter, set the barometric scale to the altimeter setting transmitted by the local automated flight service station (AFSS) or any other reliable source. The altimeter pointers should indicate the surveyed elevation of the airport. If the indication is off more than 75 feet from the surveyed elevation, the instrument should be referred to a certificated instrument repair station for recalibration. Vertical speed indicator The vertical speed indicator (VSI), which is sometimes called a vertical velocity indicator (VVI), indicates whether the airplane is climbing, descending, or in level flight. The rate of climb or descent is indicated in feet per minute. If properly calibrated, the VSI indicates zero in level flight.

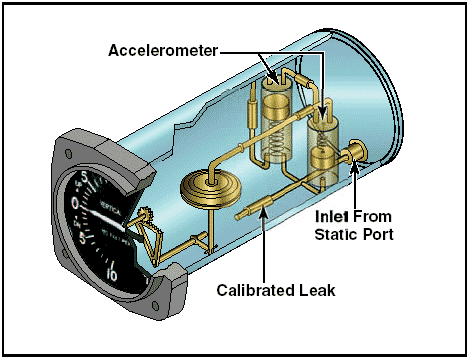

Figure 4: Vertical speed indicator. Principle of operation Although the vertical speed indicator operates solely from static pressure, it is a differential pressure instrument. It contains a diaphragm with connecting linkage and gearing to the indicator pointer inside an airtight case. The inside of the diaphragm is connected directly to the static line of the pitot-static system. The area outside the diaphragm, which is inside the instrument case, is also connected to the static line, but through a restricted orifice (calibrated leak). Both the diaphragm and the case receive air from the static line at existing atmospheric pressure. When the airplane is on the ground or in level flight, the pressures inside the diaphragm and the instrument case remain the same and the pointer is at the zero indication. When the airplane climbs or descends, the pressure inside the diaphragm changes immediately, but due to the metering action of the restricted passage, the case pressure remains higher or lower for a short time, causing the diaphragm to contract or expand. This causes a pressure differential that is indicated on the instrument needle as a climb or descent. When the pressure differential stabilizes at a definite ratio, the needle indicates the rate of altitude change. The vertical speed indicator is capable of displaying two different types of information:

For example, if maintaining a steady 500-foot per minute (f.p.m.) climb, and the nose is lowered slightly, the VSI immediately senses this change and indicates a decrease in the rate of climb. This first indication is called the trend. After a short time, the VSI needle stabilizes on the new rate of climb, which in this example, is something less than 500 f.p.m. The time from the initial change in the rate of climb, until the VSI displays an accurate indication of the new rate, is called the lag. Rough control technique and turbulence can extend the lag period and cause erratic and unstable rate indications. Some airplanes are equipped with an instantaneous vertical speed indicator (IVSI), which incorporates accelerometers to compensate for the lag in the typical VSI.

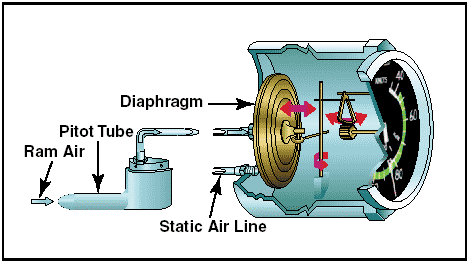

Figure 5: An instantaneous vertical speed indicator incorporates accelerometers to help the instrument immediately indicate changes in vertical speed. Instrument Check—To verify proper operation, make sure the VSI is indicating near zero prior to takeoff. After takeoff, it should indicate a positive rate of climb. Airspeed indicator The airspeed indicator is a sensitive, differential pressure gauge which measures and shows promptly the difference between pitot or impact pressure, and static pressure, the undisturbed atmospheric pressure at level flight. These two pressures will be equal when the airplane is parked on the ground in calm air. When the airplane moves through the air, the pressure on the pitot line becomes greater than the pressure in the static lines. This difference in pressure is registered by the airspeed pointer on the face of the instrument, which is calibrated in miles per hour, knots, or both.

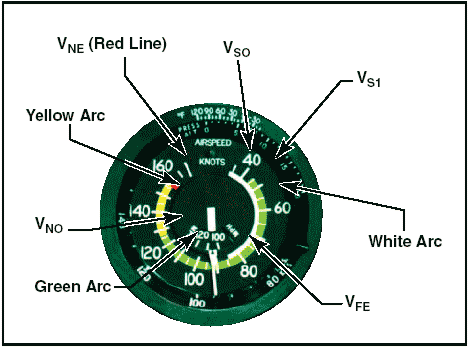

Figure 6: Airspeed indicator. Pilots should understand the following speeds: Indicated Airspeed (IAS)—The direct instrument reading obtained from the airspeed indicator, uncorrected for variations in atmospheric density, installation error, or instrument error. Manufacturers use this airspeed as the basis for determining airplane performance. Takeoff, landing, and stall speeds listed in the AFM or POH are indicated airspeeds and do not normally vary with altitude or temperature. Calibrated Airspeed (CAS)—Indicated airspeed corrected for installation error and instrument error. Although manufacturers attempt to keep airspeed errors to a minimum, it is not possible to eliminate all errors throughout the airspeed operating range. At certain airspeeds and with certain flap settings, the installation and instrument errors may total several knots. This error is generally greatest at low airspeeds. In the cruising and higher airspeed ranges, indicated airspeed and calibrated airspeed are approximately the same. Refer to the airspeed calibration chart to correct for possible airspeed errors. True Airspeed (TAS)—Calibrated airspeed corrected for altitude and nonstandard temperature. Because air density decreases with an increase in altitude, an airplane has to be flown faster at higher altitudes to cause the same pressure difference between pitot impact pressure and static pressure. Therefore, for a given calibrated airspeed, true airspeed increases as altitude increases; or for a given true airspeed, calibrated airspeed decreases as altitude increases. A pilot can find true airspeed by two methods. The most accurate method is to use a flight computer. With this method, the calibrated airspeed is corrected for temperature and pressure variation by using the airspeed correction scale on the computer. Extremely accurate electronic flight computers are also available. Just enter the CAS, pressure altitude, and temperature and the computer calculates the true airspeed. A second method, which is a “rule of thumb,” will provide the approximate true airspeed. Simply add 2 percent to the calibrated airspeed for each 1,000 feet of altitude. Groundspeed (GS)—The actual speed of the airplane over the ground. It is true airspeed adjusted for wind. Groundspeed decreases with a headwind, and increases with a tailwind. Airspeed indicator markings Airplanes weighing 12,500 pounds or less, manufactured after 1945, and certificated by the FAA, are required to have airspeed indicators marked in accordance with a standard color-coded marking system. This system of color-coded markings enables a pilot to determine at a glance certain airspeed limitations that are important to the safe operation of the airplane. For example, if during the execution of a maneuver, it is noted that the airspeed needle is in the yellow arc and rapidly approaching the red line, the immediate reaction should be to reduce airspeed.

Figure 7: In addition to delineating various speed ranges, the boundaries of the color-coded arcs also identify airspeed limitations. As shown in figure 7, airspeed indicators on single engine small airplanes include the following standard color-coded markings:

Approaches and landings are usually flown at speeds within the white arc.

Other airspeed limitations Some important airspeed limitations are not marked on the face of the airspeed indicator, but are found on placards and in the AFM or POH. These airspeeds include:

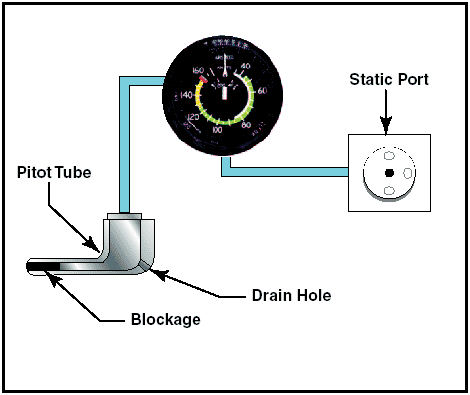

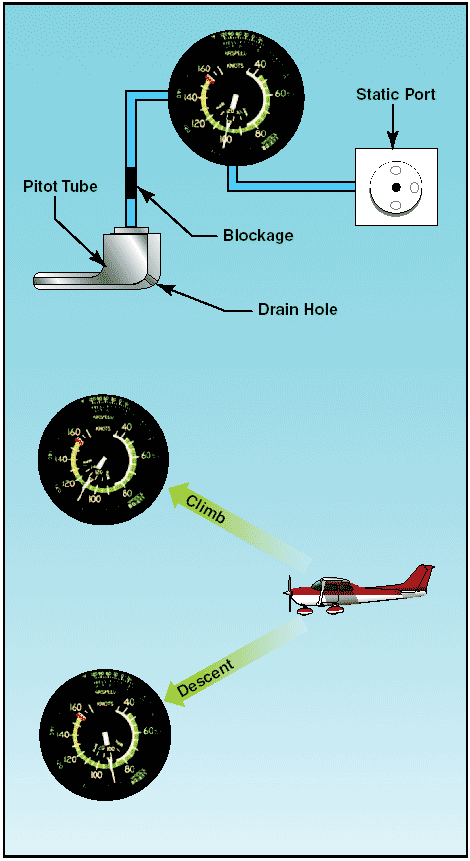

Instrument Check—Prior to takeoff, the airspeed indicator should read zero. However, if there is a strong wind blowing directly into the pitot tube, the airspeed indicator may read higher than zero. When beginning the takeoff, make sure the airspeed is increasing at an appropriate rate. Blockage of the pitot-static system Errors almost always indicate blockage of the pitot tube, the static port(s), or both. Blockage may be caused by moisture (including ice), dirt, or even insects. During preflight, make sure the pitot tube cover is removed. Then, check the pitot and static port openings. A blocked pitot tube affects the accuracy of only the airspeed indicator. However, a blockage of the static system not only affects the airspeed indicator, but can also cause errors in the altimeter and vertical speed indicator. Blocked pitot system The pitot system can become blocked completely or only partially if the pitot tube drain hole remains open. If the pitot tube becomes blocked and its associated drain hole remains clear, ram air no longer is able to enter the pitot system. Air already in the system will vent through the drain hole, and the remaining pressure will drop to ambient (outside) air pressure. Under these circumstances, the airspeed indicator reading decreases to zero, because the airspeed indicator senses no difference between ram and static air pressure. The airspeed indicator acts as if the airplane were stationary on the ramp. The apparent loss of airspeed is not usually instantaneous. Instead, the airspeed will drop toward zero.

Figure 8: A blocked pitot tube, but clear drain hole. If the pitot tube, drain hole, and static system all become blocked in flight, changes in airspeed will not be indicated, due to the trapped pressures. However, if the static system remains clear, the airspeed indicator acts as an altimeter. An apparent increase in the ram air pressure relative to static pressure occurs as altitude increases above the level where the pitot tube and drain hole became blocked. This pressure differential causes the airspeed indicator to show an increase in speed. A decrease in indicated airspeed occurs as the airplane descends below the altitude at which the pitot system became blocked.

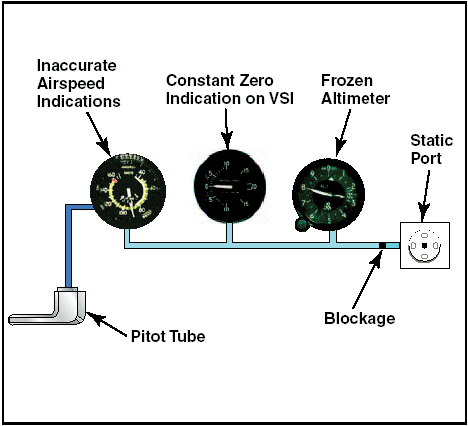

Figure 9: Blocked pitot system with clear static system. The pitot tube may become blocked during flight through visible moisture. Some airplanes may be equipped with pitot heat for flight in visible moisture. Consult the AFM or POH for specific procedures regarding the use of pitot heat. Blocked static system If the static system becomes blocked but the pitot tube remains clear, the airspeed indicator continues to operate; however, it is inaccurate. Airspeed indications are slower than the actual speed when the airplane is operated above the altitude where the static ports became blocked, because the trapped static pressure is higher than normal for that altitude. When operating at a lower altitude, a faster than actual airspeed is displayed due to the relatively low static pressure trapped in the system. A blockage of the static system also affects the altimeter and VSI. Trapped static pressure causes the altimeter to freeze at the altitude where the blockage occurred. In the case of the VSI, a blocked static system produces a continuous zero indication.

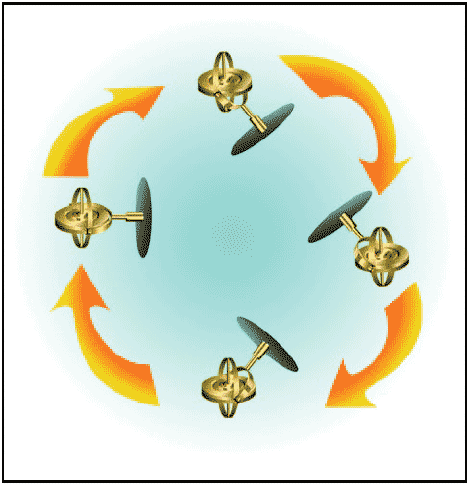

Figure 10: Blocked static system. Gyroscopic flight instruments Several flight instruments utilize the properties of a gyroscope for their operation. The most common flight instruments containing gyroscopes are the turn coordinator, heading indicator, and the attitude indicator. To understand how these flight instruments operate requires knowledge of the instrument power systems, gyroscopic principles, and the operating principles of each instrument. Gyroscopic principles Any spinning object exhibits gyroscopic properties. A wheel or rotor designed and mounted to utilize these properties is called a gyroscope. Two important design characteristics of an instrument gyro are great weight for its size, or high density, and rotation at high speed with low friction bearings. There are two general types of mountings; the type used depends upon which property of the gyro is utilized. A freely or universally mounted gyroscope is free to rotate in any direction about its center of gravity. Such a wheel is said to have three planes of freedom. The wheel or rotor is free to rotate in any plane in relation to the base and is so balanced that with the gyro wheel at rest, it will remain in the position in which it is placed. Restricted or semirigidly mounted gyroscopes are those mounted so that one of the planes of freedom is held fixed in relation to the base. There are two fundamental properties of gyroscopic action—rigidity in space and precession. Rigidity in space Rigidity in space refers to the principle that a gyroscope remains in a fixed position in the plane in which it is spinning. By mounting this wheel, or gyroscope, on a set of gimbal rings, the gyro is able to rotate freely in any direction. Thus, if the gimbal rings are tilted, twisted, or otherwise moved, the gyro remains in the plane in which it was originally spinning.

Figure 11: Regardless of the position of its base, a gyro tends to remain rigid in space, with its axis of rotation pointed in a constant direction. Precession Precession is the tilting or turning of a gyro in response to a deflective force. The reaction to this force does not occur at the point where it was applied; rather, it occurs at a point that is 90° later in the direction of rotation. This principle allows the gyro to determine a rate of turn by sensing the amount of pressure created by a change in direction. The rate at which the gyro precesses is inversely proportional to the speed of the rotor and proportional to the deflective force. Precession can also create some minor errors in some flight instruments.

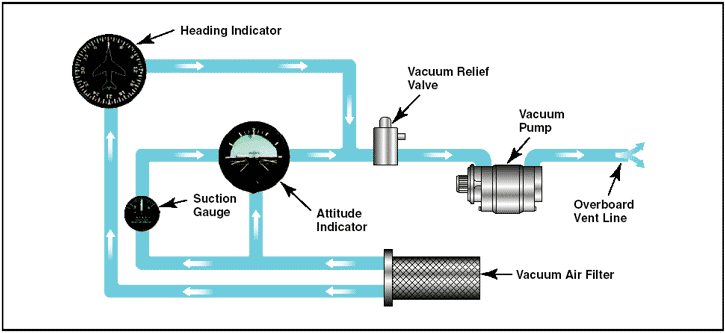

Figure 12: Precession of a gyroscope resulting from an applied deflective force. Sources of power In some airplanes, all the gyros are vacuum, pressure, or electrically operated; in others, vacuum or pressure systems provide the power for the heading and attitude indicators, while the electrical system provides the power for the turn coordinator. Most airplanes have at least two sources of power to ensure at least one source of bank information if one power source fails. The vacuum or pressure system spins the gyro by drawing a stream of air against the rotor vanes to spin the rotor at high speed, much like the operation of a waterwheel or turbine. The amount of vacuum or pressure required for instrument operation varies, but is usually between 4.5 and 5.5 in. Hg. One source of vacuum for the gyros is a vane-type engine-driven pump that is mounted on the accessory case of the engine. Pump capacity varies in different airplanes, depending on the number of gyros. A typical vacuum system consists of an engine-driven vacuum pump, relief valve, air filter, gauge, and tubing necessary to complete the connections. The gauge is mounted in the airplane’s instrument panel and indicates the amount of pressure in the system (vacuum is measured in inches of mercury less than ambient pressure).

Figure 13: Typical Vacuum System. As shown in figure 13, air is drawn into the vacuum system by the engine-driven vacuum pump. It first goes through a filter, which prevents foreign matter from entering the vacuum or pressure system. The air then moves through the attitude and heading indicators, where it causes the gyros to spin. A relief valve prevents the vacuum pressure, or suction, from exceeding prescribed limits. After that, the air is expelled overboard or used in other systems, such as for inflating pneumatic deicing boots. It is important to monitor vacuum pressure during flight, because the attitude and heading indicators may not provide reliable information when suction pressure is low. The vacuum, or suction, gauge generally is marked to indicate the normal range. Some airplanes are equipped with a warning light that illuminates when the vacuum pressure drops below the acceptable level. Turn indicators Airplanes use two types of turn indicators—the turn-and-slip indicator and the turn coordinator. Because of the way the gyro is mounted, the turn-and-slip indicator only shows the rate of turn in degrees per second. Because the gyro on the turn coordinator is set at an angle, or canted, it can initially also show roll rate. Once the roll stabilizes, it indicates rate of turn. Both flight instruments indicate turn direction and quality (coordination), and also serve as a backup source of bank information in the event an attitude indicator fails. Coordination is achieved by referring to the inclinometer, which consists of a liquid-filled curved tube with a ball inside.

Figure 14: Turn indicators rely on controlled precession for their operation.

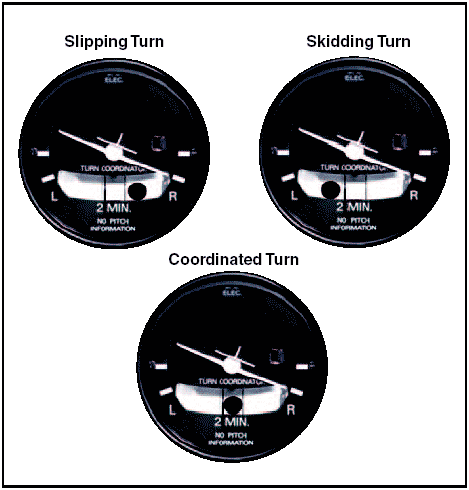

Turn-and-slip indicator The gyro in the turn-and-slip indicator rotates in the vertical plane, corresponding to the airplane’s longitudinal axis. A single gimbal limits the planes in which the gyro can tilt, and a spring tries to return it to center. Because of precession, a yawing force causes the gyro to tilt left or right as viewed from the pilot seat. The turn-and-slip indicator uses a pointer, called the turn needle, to show the direction and rate of turn. Turn coordinator The gimbal in the turn coordinator is canted; therefore, its gyro can sense both rate of roll and rate of turn. Since turn coordinators are more prevalent in training airplanes, this discussion concentrates on that instrument. When rolling into or out of a turn, the miniature airplane banks in the direction the airplane is rolled. A rapid roll rate causes the miniature airplane to bank more steeply than a slow roll rate. The turn coordinator can be used to establish and maintain a standard-rate-turn by aligning the wing of the miniature airplane with the turn index. The turn coordinator indicates only the rate and direction of turn; it does not display a specific angle of bank. Inclinometer The inclinometer is used to depict airplane yaw, which is the side-to-side movement of the airplane’s nose. During coordinated, straight-and-level flight, the force of gravity causes the ball to rest in the lowest part of the tube, centered between the reference lines. Coordinated flight is maintained by keeping the ball centered. If the ball is not centered, it can be centered by using the rudder. To do this, apply rudder pressure on the side where the ball is deflected. Use the simple rule, “step on the ball,” to remember which rudder pedal to press.

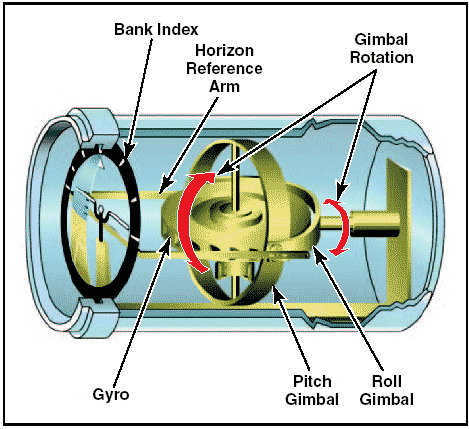

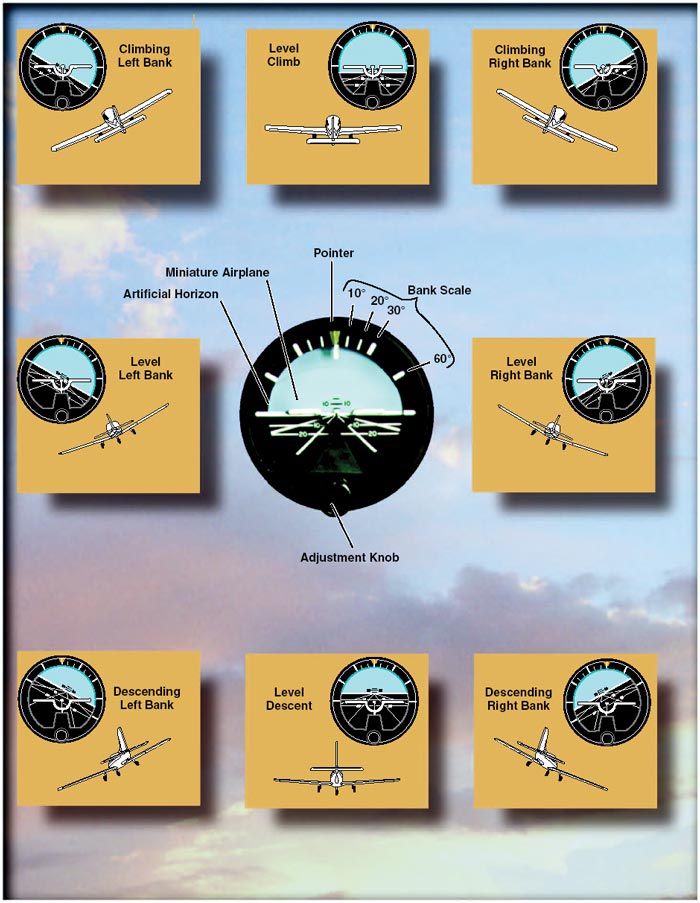

Figure 15: If inadequate right rudder is applied in a right turn, a slip results. Too much right rudder causes the airplane to skid through the turn. Centering the ball results in a coordinated turn. If aileron and rudder are coordinated during a turn, the ball remains centered in the tube. If aerodynamic forces are unbalanced, the ball moves away from the center of the tube. As shown in figure 15, in a slip, the rate of turn is too slow for the angle of bank, and the ball moves to the inside of the turn. In a skid, the rate of turn is too great for the angle of bank, and the ball moves to the outside of the turn. To correct for these conditions, and improve the quality of the turn, remember to “step on the ball.” Varying the angle of bank can also help restore coordinated flight from a slip or skid. To correct for a slip, decrease bank and/or increase the rate of turn. To correct for a skid, increase the bank and/or decrease the rate of turn. Instrument Check—During the preflight, check to see that the inclinometer is full of fluid and has no air bubbles. The ball should also be resting at its lowest point. When taxiing, the turn coordinator should indicate a turn in the correct direction. The attitude indicator The attitude indicator, with its miniature airplane and horizon bar, displays a picture of the attitude of the airplane. The relationship of the miniature airplane to the horizon bar is the same as the relationship of the real airplane to the actual horizon. The instrument gives an instantaneous indication of even the smallest changes in attitude. The gyro in the attitude indicator is mounted on a horizontal plane and depends upon rigidity in space for its operation. The horizon bar represents the true horizon. This bar is fixed to the gyro and remains in a horizontal plane as the airplane is pitched or banked about its lateral or longitudinal axis, indicating the attitude of the airplane relative to the true horizon.

Figure 16: Attitude indicator. Adjustment Gears Adjustment

An adjustment knob is provided with which the pilot may move the miniature airplane up or down to align the miniature airplane with the horizon bar to suit the pilot’s line of vision. Normally, the miniature airplane is adjusted so that the wings overlap the horizon bar when the airplane is in straight-and-level cruising flight. The pitch and bank limits depend upon the make and model of the instrument. Limits in the banking plane are usually from 100° to 110°, and the pitch limits are usually from 60° to 70°. If either limit is exceeded, the instrument will tumble or spill and will give incorrect indications until restabilized. A number of modern attitude indicators will not tumble.

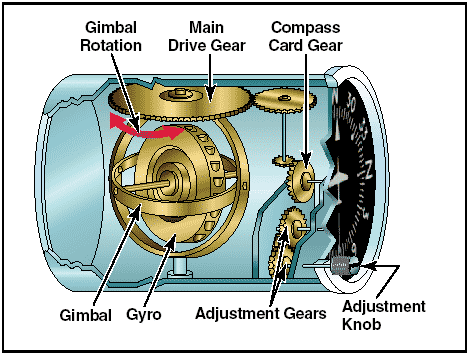

Figure 17: Attitude representation by the attitude indicator corresponds to that of the airplane to the real horizon. Every pilot should be able to interpret the banking scale illustrated in figure 17. Most banking scale indicators on the top of the instrument move in the same direction from that in which the airplane is actually banked. Some other models move in the opposite direction from that in which the airplane is actually banked. This may confuse the pilot if the indicator is used to determine the direction of bank. This scale should be used only to control the degree of desired bank. The relationship of the miniature airplane to the horizon bar should be used for an indication of the direction of bank. The attitude indicator is reliable and the most realistic flight instrument on the instrument panel. Its indications are very close approximations of the actual attitude of the airplane. Heading indicator The heading indicator (or directional gyro) is fundamentally a mechanical instrument designed to facilitate the use of the magnetic compass. Errors in the magnetic compass are numerous, making straight flight and precision turns to headings difficult to accomplish, particularly in turbulent air. A heading indicator, however, is not affected by the forces that make the magnetic compass difficult to interpret.

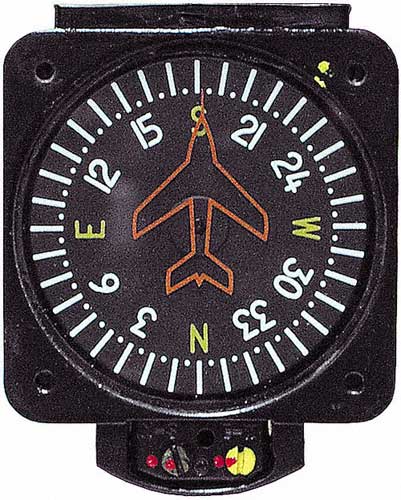

Figure 18: A heading indicator displays headings based on a 360° azimuth, with the final zero omitted. For example, a 6 represents 060°, while a 21 indicates 210°. The adjustment knob is used to align the heading indicator with the magnetic compass. The operation of the heading indicator depends upon the principle of rigidity in space. The rotor turns in a vertical plane, and fixed to the rotor is a compass card. Since the rotor remains rigid in space, the points on the card hold the same position in space relative to the vertical plane. As the instrument case and the airplane revolve around the vertical axis, the card provides clear and accurate heading information. Because of precession, caused by friction, the heading indicator will creep or drift from a heading to which it is set. Among other factors, the amount of drift depends largely upon the condition of the instrument. If the bearings are worn, dirty, or improperly lubricated, the drift may be excessive. Another error in the heading indicator is caused by the fact that the gyro is oriented in space, and the earth rotates in space at a rate of 15° in 1 hour. Thus, discounting precession caused by friction, the heading indicator may indicate as much as 15° error per every hour of operation. Some heading indicators receive a magnetic north reference from a magnetic slaving transmitter, and generally need no adjustment. Heading indicators that do not have this automatic north-seeking capability are called “free” gyros, and require periodic adjustment. It is important to check the indications frequently (approximately every 15 minutes) and reset the heading indicator to align it with the magnetic compass when required. Adjust the heading indicator to the magnetic compass heading when the airplane is straight and level at a constant speed to avoid compass errors. The bank and pitch limits of the heading indicator vary with the particular design and make of instrument. On some heading indicators found in light airplanes, the limits are approximately 55° of pitch and 55° of bank. When either of these attitude limits is exceeded, the instrument “tumbles” or “spills” and no longer gives the correct indication until reset. After spilling, it may be reset with the caging knob. Many of the modern flight instruments used are designed in such a manner that they will not tumble. Instrument Check—As the gyro spools up, make sure there are no abnormal sounds. While taxiing, the instrument should indicate turns in the correct direction, and precession should not be abnormal. At idle power settings, the gyroscopic flight instruments using the vacuum system might not be up to operating speeds and precession might occur more rapidly than during flight. Magnetic compass Since the magnetic compass works on the principle of magnetism, it is well for the pilot to have at least a basic understanding of magnetism. A simple bar magnet has two centers of magnetism which are called poles. Lines of magnetic force flow out from each pole in all directions, eventually bending around and returning to the other pole. The area through which these lines of force flow is called the field of the magnet. For the purpose of this discussion, the poles are designated “north” and “south.” If two bar magnets are placed near each other, the north pole of one will attract the south pole of the other. There is evidence that there is a magnetic field surrounding the Earth, and this theory is applied in the design of the magnetic compass. It acts very much as though there were a huge bar magnet running along the axis of the Earth which ends several hundred miles below the surface.

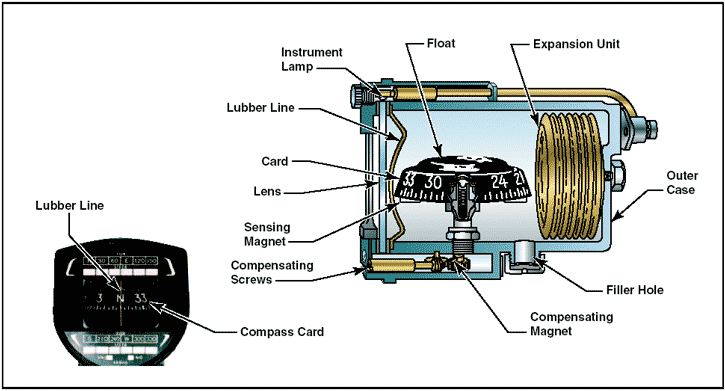

Figure 19: Earth’s magnetic field. The geographic north and south poles form the axis for the Earth’s rotation. These positions are also referred to as true north and south. Another axis is formed by the magnetic north and south poles. Lines of magnetic force flow out from each pole in all directions, and eventually return to the opposite pole. A compass aligns itself with the magnetic axis formed by the north/south magnetic field of the Earth. The lines of force have a vertical component (or pull) which is zero at the Equator, but builds to 100 percent of the total force at the magnetic poles. If magnetic needles, such as in the airplane’s magnetic compass, are held along these lines of force, the vertical component causes one end of the needle to dip or deflect downward. The amount of dip increases as the needles are moved closer and closer to the poles. It is this deflection, or dip, that causes some of the larger compass errors. The magnetic compass, which is usually the only direction-seeking instrument in the airplane, is simple in construction. It contains two steel magnetized needles fastened to a float, around which is mounted a compass card. The needles are parallel, with their north-seeking ends pointing in the same direction. The compass card has letters for cardinal headings, and each 30° interval is represented by a number, the last zero of which is omitted. For example, 30° appears as a 3 and 300° appears as a 30. Between these numbers, the card is graduated for each 5°. The magnetic compass is required equipment in all airplanes. It is used to set the gyroscopic heading indicator, correct for precession, and as a backup in the event the heading indicator(s) fails.

Figure 20: Magnetic compass.

Compass errors

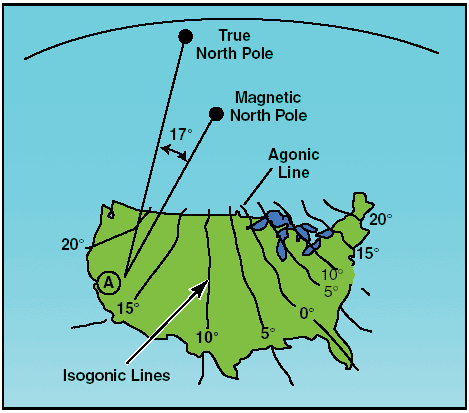

Variation Although the magnetic field of the Earth lies roughly north and south, the Earth’s magnetic poles do not coincide with its geographic poles, which are used in the construction of aeronautical charts. Consequently, at most places on the Earth’s surface, the direction-sensitive steel needles that seek the Earth’s magnetic field will not point to true north, but to magnetic north. Furthermore, local magnetic fields from mineral deposits and other conditions may distort the Earth’s magnetic field, and cause additional error in the position of the compass’ north-seeking magnetized needles with reference to true north. The angular difference between magnetic north, the reference for the magnetic compass, and true north is variation. Lines that connect points of equal variation are called isogonic lines. The line connecting points where the magnetic variation is zero is an agonic line. To convert from true courses or headings to magnetic, subtract easterly variation and add westerly variation. Reverse the process to convert from magnetic to true.

Figure 21: Variation at point A in the western United States is 17°. Since the magnetic north pole is located to the east of the true north pole in relation to this point, the variation is easterly. When the magnetic pole falls to the west of the true north pole, variation is westerly. Compass deviation Besides the magnetic fields generated by the Earth, other magnetic fields are produced by metal and electrical accessories within the airplane. These magnetic fields distort the Earth’s magnetic force, and cause the compass to swing away from the correct heading. This error is called deviation. Manufacturers install compensating magnets within the compass housing to reduce the effects of deviation. The magnets are usually adjusted while the engine is running and all electrical equipment is operating. However, it is not possible to completely eliminate deviation error; therefore, a compass correction card is mounted near the compass. This card corrects for deviation that occurs from one heading to the next as the lines of force interact at different angles.

Figure 22: Compass correction card. Magnetic dip Magnetic dip is the result of the vertical component of the Earth’s magnetic field. This dip is virtually non-existent at the magnetic equator, since the lines of force are parallel to the Earth’s surface and the vertical component is minimal. When a compass is moved toward the poles, the vertical component increases, and magnetic dip becomes more apparent at higher latitudes. Magnetic dip is responsible for compass errors during acceleration, deceleration, and turns. Using the magnetic compass

Acceleration/deceleration errors Acceleration and deceleration errors are fluctuations in the compass during changes in speed. In the Northern Hemisphere, the compass swings towards the north during acceleration, and towards the south during deceleration. When the speed stabilizes, the compass returns to an accurate indication. This error is most pronounced when flying on a heading of east or west, and decreases gradually when flying closer to a north or south heading. The error does not occur when flying directly north or south. The memory aid, ANDS (Accelerate North, Decelerate South) may help in recalling this error. In the Southern Hemisphere, this error occurs in the opposite direction. Turning errors Turning errors are most apparent when turning to or from a heading of north or south. This error increases as the poles are neared and magnetic dip becomes more apparent. There is no turning error when flying near the magnetic equator. In the Northern Hemisphere, when making a turn from a northerly heading, the compass gives an initial indication of a turn in the opposite direction. It then begins to show the turn in the proper direction, but lags behind the actual heading. The amount of lag decreases as the turn continues, then disappears as the airplane reaches a heading of east or west. When turning from a heading of east or west to a heading of north, there is no error as the turn begins. However, as the heading approaches north, the compass increasingly lags behind the airplane’s actual heading. When making a turn from a southerly heading, the compass gives an indication of a turn in the correct direction, but leads the actual heading. This error also disappears as the airplane approaches an east or west heading. Turning from east or west to a heading of south causes the compass to move correctly at the start of a turn, but then it increasingly leads the actual heading as the airplane nears a southerly direction. The amount of lead or lag is approximately equal to the latitude of the airplane. For example, if turning from a heading of south to a heading of west while flying at 40° north latitude, the compass rapidly turns to a heading of 220° (180° + 40°). At the midpoint of the turn, the lead decreases to approximately half (20°), and upon reaching a heading of west, it is zero. The magnetic compass, which is the only direction-seeking instrument in the airplane, should be read only when the airplane is flying straight and level at a constant speed. This will help reduce errors to a minimum. If the pilot thoroughly understands the errors and characteristics of the magnetic compass, this instrument can become the most reliable means of determining headings. Instrument Check—Prior to flight, make sure that the compass is full of fluid. Then during turns, the compass should swing freely and indicate known headings. Vertical card compass A newer design, the vertical card compass significantly reduces the inherent error of the older compass designs. It consists of an azimuth on a rotating vertical card, and resembles a heading indicator with a fixed miniature airplane to accurately present the heading of the airplane. The presentation is easy to read, and the pilot can see the complete 360° dial in relation to the airplane heading. This design uses eddy current damping to minimize lead and lag during turns.

Figure 23: Vertical card compass. Outside air temperature gauge The outside air temperature gauge (OAT) is a simple and effective device mounted so that the sensing element is exposed to the outside air. The sensing element consists of a bimetallic-type thermometer in which two dissimilar materials are welded together in a single strip and twisted into a helix. One end is anchored into protective tube and the other end is affixed to the pointer, which reads against the calibration on a circular face. OAT gauges are calibrated in degrees Celsius, Fahrenheit, or both. An accurate air temperature will provide the pilot with useful information about temperature lapse rate with altitude change.

Figure 24: Outside air temperature gauge. This concludes the Flight Instruments page. You can now go on to the Airplane Aerodynamics page or test your knowledge with the FAA Principles of Flight question bank. |